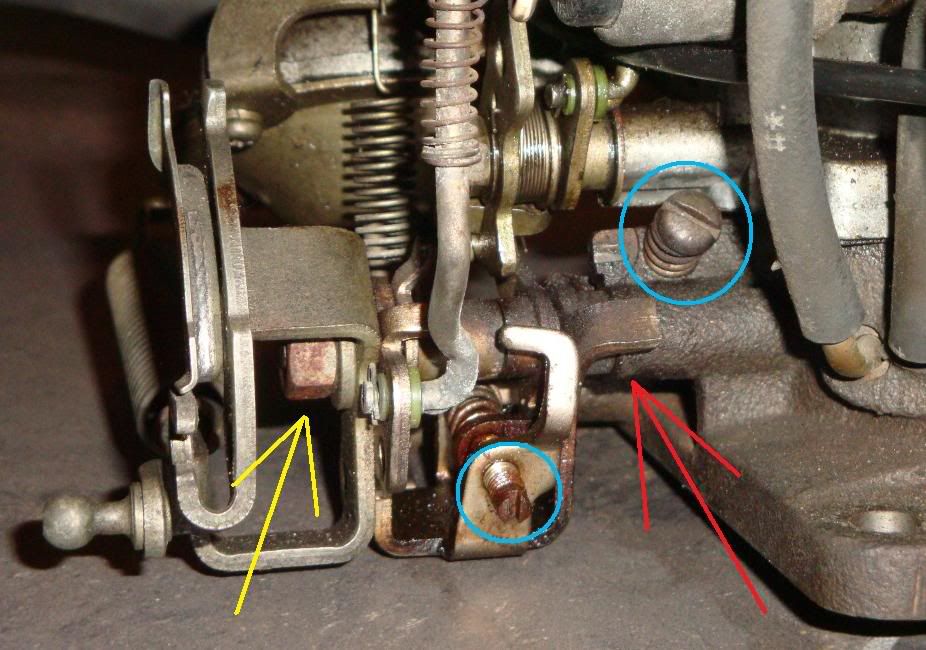

After consulting the FSM, fiddling with all the usual idle screws (blue circles below) and using carb cleaner to ensure that the throttle open/close action is smooth and reliable (spraying liberlly - with emphasis on the points indicated with arrows), I'm still experiencing problems achieving a reasonable idle speed. I know this much: I can blip my throttle and wait for the high idle condition to occur (which it does every time). To correct for this, I can simply hand guide my throttle lever (the curved bit with the knob at the bottom left of the photo) backwards to achieve 800 RPM. The difference in throttle position between ~1,500 RPM and 800 RPM is frustratingly small!

I'm thinking that my butterfly valves at the very base of my carb are at fault here because while the throttle snaps shut with adequate force/reliability, there's still that extra 1,000th of an inch of throttle position return that is needed to return the system to proper idle conditions. If this is the case, then a simple removal and cleaning is probably in order. Does this theory sound feasible to anyone? Does anyone have experience with this, or an alternate theory?

Ps - I know the Weber would eliminate all of my fuel delivery woes, but I'm just not ready to drop $300 on one part at this point, so that's off the table for now. *Thanks!*