Dealing with extra horsepower and torque

-

4wdchico

- Highest Ranking Member

- Posts: 563

- Joined: Sun Mar 30, 2008 6:51 pm

- My tercel:: 1985 tercel 4wd

- Location: Chico, Norcal

Re: Dealing with extra horsepower and torque

Synth,

Is the 4wd lever moving excessively forward and back or side to side when the torque is applied/removed?

Is the 4wd lever moving excessively forward and back or side to side when the torque is applied/removed?

- Petros

- Highest Ranking Member

- Posts: 11933

- Joined: Sun Jan 28, 2007 6:31 pm

- My tercel:: '84 Tercel4wd w/extensive mods

- Location: Arlington WA USA

Re: Dealing with extra horsepower and torque

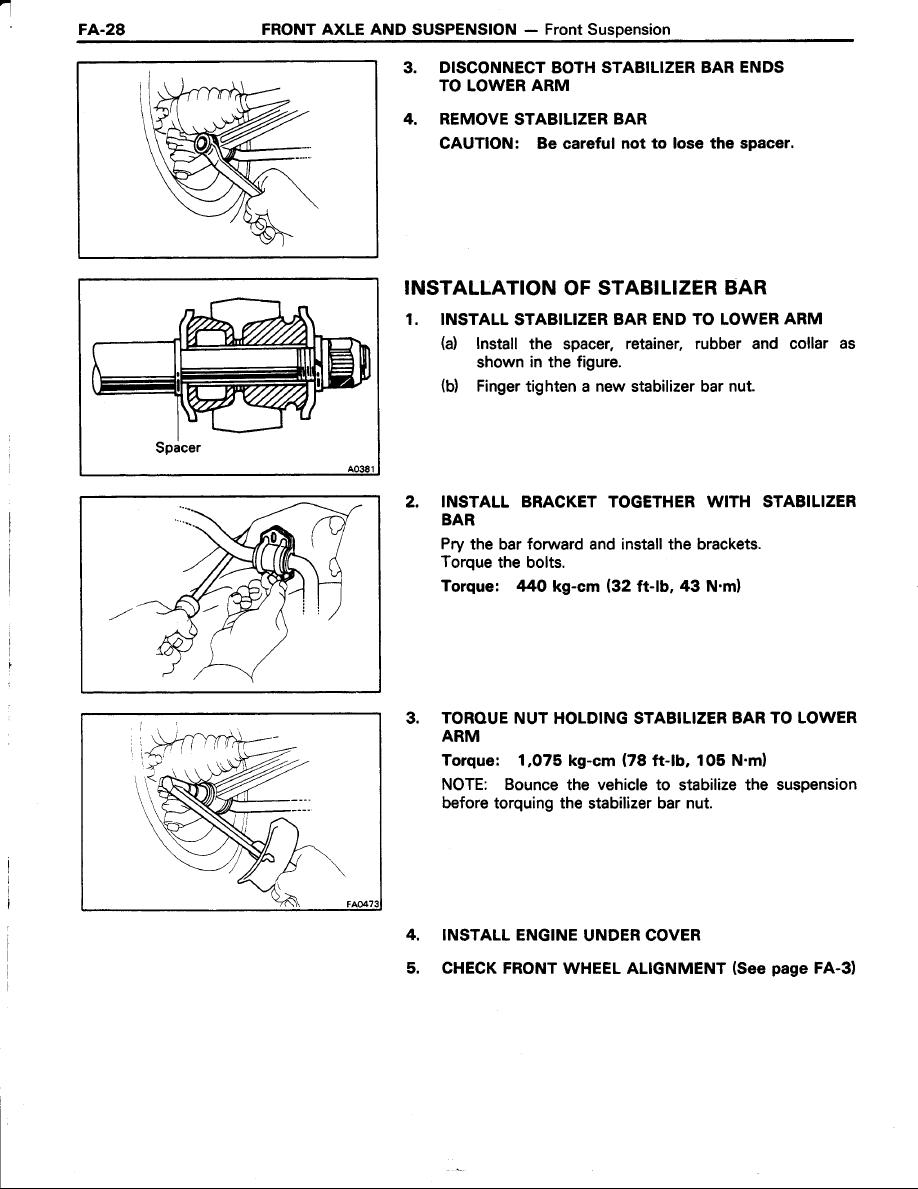

This is the the cross section of the front stabilizer bar bushing (from the FSM). This looks like a pretty squishy way to locate a drive wheel, and the wheel that steers the car, to me. There appears nothing spherical there at all. I have some first gen MR2 rear suspension parts I am going to look at to see if the bushings are close enough to use, it would be nice to buy something that is more stiff rather than having to make it. Making nylon ball and cup fittings to replace the hollow rubber parts might be best way to fix the issue.

'87 Tercel 4wd SR5 (current engine swap project)

'84 Tercel 4wd (daily driver, with on going mods)

'92 Mazda MPV 4wd (wife's daily driver)

'85 Tercel 4wd DLX auto(daughter's daily driver)

'01 Honda Civic (other daughter's daily driver)

'84 Tercel 4wd (daily driver, with on going mods)

'92 Mazda MPV 4wd (wife's daily driver)

'85 Tercel 4wd DLX auto(daughter's daily driver)

'01 Honda Civic (other daughter's daily driver)

-

SynthDesign

- Highest Ranking Member

- Posts: 826

- Joined: Mon Oct 27, 2008 5:42 pm

- My tercel:: The General, 85 SR5 w/ Sunroof,Olive Drab paint, Black Interior, custom steel bumpers, Barto BC lift, 1.67L BUILT 3AC w/ Weber Carb. 346,000 miles and counting since restoration

- Location: Seattle WA

- Contact:

Re: Dealing with extra horsepower and torque

Thanks Barto. Is 2" really required for the strut spacers? A three inch lifted 4runner only uses a 1.5 inch spacer.

How'd you come up with 5/8" for the frame spacers? Not that I question you, was just curious how you came up with it .

@4wdchico, Oh yea. Lots. I had to shorten the 4wd linkage because it was making noise and already made a dent in the unibody from slapping it repetitively.

How'd you come up with 5/8" for the frame spacers? Not that I question you, was just curious how you came up with it .

@4wdchico, Oh yea. Lots. I had to shorten the 4wd linkage because it was making noise and already made a dent in the unibody from slapping it repetitively.

Vintage and Classic Toyota; Have you loved your Toyota today?

2016 Toyota Tacoma Quad Cab LB TRD OffRoad

2005 Toyota Sienna, work van

85 Toyota Tercel SR5 4wd (The General)

85 Toyota Tercel GTS 4wd (4AGE Swap)

85 Toyota MR2 (Blu)

83 Mazda RX-7 Mariah Widebody

2016 Toyota Tacoma Quad Cab LB TRD OffRoad

2005 Toyota Sienna, work van

85 Toyota Tercel SR5 4wd (The General)

85 Toyota Tercel GTS 4wd (4AGE Swap)

85 Toyota MR2 (Blu)

83 Mazda RX-7 Mariah Widebody

-

SynthDesign

- Highest Ranking Member

- Posts: 826

- Joined: Mon Oct 27, 2008 5:42 pm

- My tercel:: The General, 85 SR5 w/ Sunroof,Olive Drab paint, Black Interior, custom steel bumpers, Barto BC lift, 1.67L BUILT 3AC w/ Weber Carb. 346,000 miles and counting since restoration

- Location: Seattle WA

- Contact:

Re: Dealing with extra horsepower and torque

So, in thinking, the strut spacers raise the pitch of the CV Axles. I installed a set of 10mm engine cross member spacers. This was the max I could use w/o replacing the cross member bolts. It didn't stop the clunks but leveled out the CV Axle pitch.

I'm totally thinkin the clunk is the front diff still. Maybe replacing the control arm bushings will help....

I'm totally thinkin the clunk is the front diff still. Maybe replacing the control arm bushings will help....

Vintage and Classic Toyota; Have you loved your Toyota today?

2016 Toyota Tacoma Quad Cab LB TRD OffRoad

2005 Toyota Sienna, work van

85 Toyota Tercel SR5 4wd (The General)

85 Toyota Tercel GTS 4wd (4AGE Swap)

85 Toyota MR2 (Blu)

83 Mazda RX-7 Mariah Widebody

2016 Toyota Tacoma Quad Cab LB TRD OffRoad

2005 Toyota Sienna, work van

85 Toyota Tercel SR5 4wd (The General)

85 Toyota Tercel GTS 4wd (4AGE Swap)

85 Toyota MR2 (Blu)

83 Mazda RX-7 Mariah Widebody

I notice in the drawing, the bushing thats on the front side of the arm has a white area inside of it? Is that metal inside of the bushing, or just air? The control arm is gonna pull forward under acceleration, right? the back bushing looks like solid rubber so it would be squishier under braking. both bushings would have to flex to let the arm go up and down without binding. If you used solid bushings it seems like it might snap off the threaded portion of the sway bar, and or put more stress on the frame sway bushings?

I work as a machinist, at a plastic industrial bearing manufacturer. I would love to make some bushings, but I'm not sure exactly how to make em. The plastic bushings we make are very rigid, and hardly flex.

I was thinking make the front ones a solid ball socket like setup, and use the rear stock ones, or vice versa.

I need to do my sway control bushings soon, but I cannot afford to have my car not working for too long as its my daily driver. I just ordered a set from toyota for now.

I'd be willing to make something if someone has an idea for this.

I work as a machinist, at a plastic industrial bearing manufacturer. I would love to make some bushings, but I'm not sure exactly how to make em. The plastic bushings we make are very rigid, and hardly flex.

I was thinking make the front ones a solid ball socket like setup, and use the rear stock ones, or vice versa.

I need to do my sway control bushings soon, but I cannot afford to have my car not working for too long as its my daily driver. I just ordered a set from toyota for now.

I'd be willing to make something if someone has an idea for this.

- Petros

- Highest Ranking Member

- Posts: 11933

- Joined: Sun Jan 28, 2007 6:31 pm

- My tercel:: '84 Tercel4wd w/extensive mods

- Location: Arlington WA USA

Re: Dealing with extra horsepower and torque

I have some preliminary sketches of how a plastic ball and socket busing would work. I just to not have an easy way of making any (a drill press and a file?). That was why I was considering adapting something already available.

It is not a new idea, but no one has made one for this application. Yes, the half ball and socket would go in the front with the stock one in the back allow some give in the joint. There would be less stress on the sway bar end since the ball and socket would be a half shear pivoting in a socket rather than a rubber bushing compressing. Dust and grit might make it wear, but if we can find a suitable boot to cover it with it would stay clean.

Considering how expensive the stock bushings are, and there is nowhere else to buy them, this would not be a bad idea to make up 30 or 40 kits and make them available. Could even sell them on-line.

It is not a new idea, but no one has made one for this application. Yes, the half ball and socket would go in the front with the stock one in the back allow some give in the joint. There would be less stress on the sway bar end since the ball and socket would be a half shear pivoting in a socket rather than a rubber bushing compressing. Dust and grit might make it wear, but if we can find a suitable boot to cover it with it would stay clean.

Considering how expensive the stock bushings are, and there is nowhere else to buy them, this would not be a bad idea to make up 30 or 40 kits and make them available. Could even sell them on-line.

'87 Tercel 4wd SR5 (current engine swap project)

'84 Tercel 4wd (daily driver, with on going mods)

'92 Mazda MPV 4wd (wife's daily driver)

'85 Tercel 4wd DLX auto(daughter's daily driver)

'01 Honda Civic (other daughter's daily driver)

'84 Tercel 4wd (daily driver, with on going mods)

'92 Mazda MPV 4wd (wife's daily driver)

'85 Tercel 4wd DLX auto(daughter's daily driver)

'01 Honda Civic (other daughter's daily driver)

Re: Dealing with extra horsepower and torque

Sweet, consider me onboard. I can make anything on our cnc lathe down to about .001 tolerance. I like the idea of using it with the stock bushing. Are you thinking of making it with a large radius, possibly to match the radius the arm makes? if you want to send me your sketches, I could whip up a batch.

The material I am gonna use is called D-Glide fc, it's supposed to be good at resisting abrasive wear, self lubricated, and it is practically indestructable.

http://www.drie-d.nl/p/35/75/mo64-m4/d- ... n-bearings

The material I am gonna use is called D-Glide fc, it's supposed to be good at resisting abrasive wear, self lubricated, and it is practically indestructable.

http://www.drie-d.nl/p/35/75/mo64-m4/d- ... n-bearings

- Petros

- Highest Ranking Member

- Posts: 11933

- Joined: Sun Jan 28, 2007 6:31 pm

- My tercel:: '84 Tercel4wd w/extensive mods

- Location: Arlington WA USA

Re: Dealing with extra horsepower and torque

Perfect material for this application.

I had several ideas, even using two half spheres, one on each side, to make a real solid connection. But that would have be be made very accurately or you would get binding. The typical approach is to use the ball and cup on one side, and the rubber bushing on the other. The hole where the end of the sway bar goes through would have to be slotted to allow it flex, and there would be some clearance issues to accommodate. I see if I can get a proper drawing made and get it scanned and posted.

I had several ideas, even using two half spheres, one on each side, to make a real solid connection. But that would have be be made very accurately or you would get binding. The typical approach is to use the ball and cup on one side, and the rubber bushing on the other. The hole where the end of the sway bar goes through would have to be slotted to allow it flex, and there would be some clearance issues to accommodate. I see if I can get a proper drawing made and get it scanned and posted.

'87 Tercel 4wd SR5 (current engine swap project)

'84 Tercel 4wd (daily driver, with on going mods)

'92 Mazda MPV 4wd (wife's daily driver)

'85 Tercel 4wd DLX auto(daughter's daily driver)

'01 Honda Civic (other daughter's daily driver)

'84 Tercel 4wd (daily driver, with on going mods)

'92 Mazda MPV 4wd (wife's daily driver)

'85 Tercel 4wd DLX auto(daughter's daily driver)

'01 Honda Civic (other daughter's daily driver)

-

SynthDesign

- Highest Ranking Member

- Posts: 826

- Joined: Mon Oct 27, 2008 5:42 pm

- My tercel:: The General, 85 SR5 w/ Sunroof,Olive Drab paint, Black Interior, custom steel bumpers, Barto BC lift, 1.67L BUILT 3AC w/ Weber Carb. 346,000 miles and counting since restoration

- Location: Seattle WA

- Contact:

Re: Dealing with extra horsepower and torque

The area shown White in the diagram is actually durlon plastic. If you've work out the sway link end bushings, it's normally the only thing left.

I'm quite curious what you guys can come up with. A heavy duty macro-plastic bushing would be sweet. I'd be down for a set or two. For the deflection tolerances, how bought an elastomer collar. A 1500lb tuber type would only give a mm or two and work like a washer

I still think we need to hard mount the control arm to the frame and redo the sway bar. Just kinda hard to do since Toyota put so much engineering into each car.

As for the initial problem. I've solved a few of my clunks and still have a huge amount of engine and trans movement. I ordered a hydraulic dampener kit from ebay. I'm gonna play around with it. It looks very close to our factory engine dampener but with ball joints on the end. I'm pretty sure they're threaded on too.

I should be able to mount it to the top of the strut tower or integrate in into a strut tower bar.

I'm quite curious what you guys can come up with. A heavy duty macro-plastic bushing would be sweet. I'd be down for a set or two. For the deflection tolerances, how bought an elastomer collar. A 1500lb tuber type would only give a mm or two and work like a washer

I still think we need to hard mount the control arm to the frame and redo the sway bar. Just kinda hard to do since Toyota put so much engineering into each car.

As for the initial problem. I've solved a few of my clunks and still have a huge amount of engine and trans movement. I ordered a hydraulic dampener kit from ebay. I'm gonna play around with it. It looks very close to our factory engine dampener but with ball joints on the end. I'm pretty sure they're threaded on too.

I should be able to mount it to the top of the strut tower or integrate in into a strut tower bar.

Vintage and Classic Toyota; Have you loved your Toyota today?

2016 Toyota Tacoma Quad Cab LB TRD OffRoad

2005 Toyota Sienna, work van

85 Toyota Tercel SR5 4wd (The General)

85 Toyota Tercel GTS 4wd (4AGE Swap)

85 Toyota MR2 (Blu)

83 Mazda RX-7 Mariah Widebody

2016 Toyota Tacoma Quad Cab LB TRD OffRoad

2005 Toyota Sienna, work van

85 Toyota Tercel SR5 4wd (The General)

85 Toyota Tercel GTS 4wd (4AGE Swap)

85 Toyota MR2 (Blu)

83 Mazda RX-7 Mariah Widebody

Re: Dealing with extra horsepower and torque

i use in mine polyurethane 95 shure a hardness, i make them here in the shop. They last a couple of years, ive tried them with graphite/polyurethane and just polyurethane and they work the same

tercel 4wd custom suspension, under drive pulley, vented brakes, cold air intake, and plenty more to come

-

PrescottAZ

- Top Notch Member

- Posts: 115

- Joined: Mon Nov 01, 2010 4:03 pm

- My tercel:: 83 4wd, jeep cherokee front springs in rear, cut fenders, mr2 booster, gauge swap for tach, Suzuki Katana 600 Carbs, 330,000 miles and ticking (literally)

- Location: Prescott Arizona

- Contact:

Re: Dealing with extra horsepower and torque

Why not design a setup where you ditch the sway bar and mount a longer control arm on the backside? No more sway bar affecting your flexing and getting in the way of entry angles. The new control arm could be set up for a lifted height. Like what you see on lifted trucks. If you are going through all the trouble of designing something so cool you should go all the way. Just my 2 cents. That is what I plan on doing combined with much stiffer springs, different struts and 2" drivetrain drop. Then I will use the stock mounting points for the stock sway bar for a skid plate mounting point.

I will be doing a bike carbed silver top though. I have the bike carbs and will most likely be putting them on the 3ac to start getting used to tuning them and the stocker is crapping out (leaking, cant hold idle well and has so many flat spots I am not sure what to call it).

It is strange you are having such dramatic trouble with the engine hopping around. I had a 5afc twin cam in there with a custom built 4-2-1 header, 2.5" full exhaust and a webber that was way more powerfull than stock with none of those problems. Maybe the torque wasn't as high as yours...

On the other hand, I am sure more people will be interested in it if it is useable in stock form and does not require extreme modifications. Kinda boring.

I will be doing a bike carbed silver top though. I have the bike carbs and will most likely be putting them on the 3ac to start getting used to tuning them and the stocker is crapping out (leaking, cant hold idle well and has so many flat spots I am not sure what to call it).

It is strange you are having such dramatic trouble with the engine hopping around. I had a 5afc twin cam in there with a custom built 4-2-1 header, 2.5" full exhaust and a webber that was way more powerfull than stock with none of those problems. Maybe the torque wasn't as high as yours...

On the other hand, I am sure more people will be interested in it if it is useable in stock form and does not require extreme modifications. Kinda boring.

- Petros

- Highest Ranking Member

- Posts: 11933

- Joined: Sun Jan 28, 2007 6:31 pm

- My tercel:: '84 Tercel4wd w/extensive mods

- Location: Arlington WA USA

Re: Dealing with extra horsepower and torque

Hey PrescottAZ,

What did you have a 5afc in? Not a Tercel4wd was it?

It sounds like your current carb, or several vacuum lines, are leaking. Tyipically when you get symptoms like that you have multiple vacuum leaks, or the hose are connected wrong. Trace through all the lines with the vac diagram from the FSM and check to cracked or leaky hoses, use carb cleaner spary to find leaks, and than remove the top of the carb carefully and clean it out. That usually solves idle and flat spot issues.

Also you can not just dump the front sway bar, it is used to locate the lateral link fore-and-aft. IOW, it forms a sort of A-arm between the lateral link or lower arm and the sway bar. It helps locate the wheel, you would have to replace the sway bar with a new strut or link with a pivot at the front or body end and perhaps a solid mount where the sway bar attaches to the lower arm. And you would still need to rig some kind of anti-sway bar or you would end up with killer oversteer, or have springs so stiff it would almost act like it had no suspension at all on hwy driving.

Removing it would not change the entry angle anyway, that is that massive bumper. Wheel travel is limited by the strut, not the sway bar anyway.

What did you have a 5afc in? Not a Tercel4wd was it?

It sounds like your current carb, or several vacuum lines, are leaking. Tyipically when you get symptoms like that you have multiple vacuum leaks, or the hose are connected wrong. Trace through all the lines with the vac diagram from the FSM and check to cracked or leaky hoses, use carb cleaner spary to find leaks, and than remove the top of the carb carefully and clean it out. That usually solves idle and flat spot issues.

Also you can not just dump the front sway bar, it is used to locate the lateral link fore-and-aft. IOW, it forms a sort of A-arm between the lateral link or lower arm and the sway bar. It helps locate the wheel, you would have to replace the sway bar with a new strut or link with a pivot at the front or body end and perhaps a solid mount where the sway bar attaches to the lower arm. And you would still need to rig some kind of anti-sway bar or you would end up with killer oversteer, or have springs so stiff it would almost act like it had no suspension at all on hwy driving.

Removing it would not change the entry angle anyway, that is that massive bumper. Wheel travel is limited by the strut, not the sway bar anyway.

Last edited by Petros on Tue Apr 19, 2011 11:59 am, edited 1 time in total.

'87 Tercel 4wd SR5 (current engine swap project)

'84 Tercel 4wd (daily driver, with on going mods)

'92 Mazda MPV 4wd (wife's daily driver)

'85 Tercel 4wd DLX auto(daughter's daily driver)

'01 Honda Civic (other daughter's daily driver)

'84 Tercel 4wd (daily driver, with on going mods)

'92 Mazda MPV 4wd (wife's daily driver)

'85 Tercel 4wd DLX auto(daughter's daily driver)

'01 Honda Civic (other daughter's daily driver)

-

PrescottAZ

- Top Notch Member

- Posts: 115

- Joined: Mon Nov 01, 2010 4:03 pm

- My tercel:: 83 4wd, jeep cherokee front springs in rear, cut fenders, mr2 booster, gauge swap for tach, Suzuki Katana 600 Carbs, 330,000 miles and ticking (literally)

- Location: Prescott Arizona

- Contact:

Re: Dealing with extra horsepower and torque

Yup in my last turd I have pictures somewhere. I sold it a while back. JDM motor got it for like 210 shipped from risingsun engines. Beat the crap out of the fire wall with a sledge for the distributer and built an exhaust from an aftermarket 4afe fwd manifold. Cut it up and re welded to make it rwd. Wish I never sold it. Weber didn't fit so I chopped a hole in the hood for the air cleaner. Wife hated it. I only did a 5/8" shim for the drivetrain drop. That would be a new thread though.

What I plan to do is throw away the sway bar and make a new link that attaches to LCA at the same point as the sway bar does now but from from the cab side of the vehicle. Jeep coils on RAV4 struts. Plenty of cars roll the streets w/o sway bars. (My wifes 01 cavalier coupe is one example from the factory.) I removed the flimsy thing on the rear toyota called a sway bar when I put jeep springs back there and it feels good. Once I get rid of the front bar there will be less three wheelin going on if you know what I mean.

What I plan to do is throw away the sway bar and make a new link that attaches to LCA at the same point as the sway bar does now but from from the cab side of the vehicle. Jeep coils on RAV4 struts. Plenty of cars roll the streets w/o sway bars. (My wifes 01 cavalier coupe is one example from the factory.) I removed the flimsy thing on the rear toyota called a sway bar when I put jeep springs back there and it feels good. Once I get rid of the front bar there will be less three wheelin going on if you know what I mean.

-

PrescottAZ

- Top Notch Member

- Posts: 115

- Joined: Mon Nov 01, 2010 4:03 pm

- My tercel:: 83 4wd, jeep cherokee front springs in rear, cut fenders, mr2 booster, gauge swap for tach, Suzuki Katana 600 Carbs, 330,000 miles and ticking (literally)

- Location: Prescott Arizona

- Contact:

Re: Dealing with extra horsepower and torque

What bumpers? Massive bumpers already removed. They came off when I attacked my fenders with an angle grinder!

If I drop the drive train 2" the sway bar and such goes down with it.

I have hit that swaybar mount before off road. Want it to be a skid plate attachment point.

Okay I am jacking the thread sorry I am done.

Window weld in engine mounts is a big thumbs up. But can lead to more noise if it isn't the problem as it will send more force/stress somewhere else. If the drivetrain has play you could be hearing that slapping around when the engine rocks back and forth. Check everything that goes to the back to make sure it doesn't allow for front to back play cause that will make noise. At least that was my problem in my RAV4.

Aren't there cool mounts for AE86's that could be modified to work?

Also double check how tight everything is bolted down or up. You'd be surprised what decides to work its way loose. Also things crack and chances are your battery tray has been leaking goodness down onto the engine crossmember. Cracks are not impossible and would explain movement and noise.

If I drop the drive train 2" the sway bar and such goes down with it.

I have hit that swaybar mount before off road. Want it to be a skid plate attachment point.

Okay I am jacking the thread sorry I am done.

Window weld in engine mounts is a big thumbs up. But can lead to more noise if it isn't the problem as it will send more force/stress somewhere else. If the drivetrain has play you could be hearing that slapping around when the engine rocks back and forth. Check everything that goes to the back to make sure it doesn't allow for front to back play cause that will make noise. At least that was my problem in my RAV4.

Aren't there cool mounts for AE86's that could be modified to work?

Also double check how tight everything is bolted down or up. You'd be surprised what decides to work its way loose. Also things crack and chances are your battery tray has been leaking goodness down onto the engine crossmember. Cracks are not impossible and would explain movement and noise.

-

SynthDesign

- Highest Ranking Member

- Posts: 826

- Joined: Mon Oct 27, 2008 5:42 pm

- My tercel:: The General, 85 SR5 w/ Sunroof,Olive Drab paint, Black Interior, custom steel bumpers, Barto BC lift, 1.67L BUILT 3AC w/ Weber Carb. 346,000 miles and counting since restoration

- Location: Seattle WA

- Contact:

Re: Dealing with extra horsepower and torque

PrescottAZ, all good

I'm convinced a proper engine dampener would solve a lot of my issues. I swapped to a way worn out 4WD linkage and that noise stopped. The exhaust seems to keep working itself loose too.

My chassis is about perfect. I stripped it almost bare for the restore. Urethane mounts could help a bit too.. but a big chunk of money. I may try my and at poly'n some worn out factory mounts. I ordered the 95a as recommended.

I'm convinced a proper engine dampener would solve a lot of my issues. I swapped to a way worn out 4WD linkage and that noise stopped. The exhaust seems to keep working itself loose too.

My chassis is about perfect. I stripped it almost bare for the restore. Urethane mounts could help a bit too.. but a big chunk of money. I may try my and at poly'n some worn out factory mounts. I ordered the 95a as recommended.

Vintage and Classic Toyota; Have you loved your Toyota today?

2016 Toyota Tacoma Quad Cab LB TRD OffRoad

2005 Toyota Sienna, work van

85 Toyota Tercel SR5 4wd (The General)

85 Toyota Tercel GTS 4wd (4AGE Swap)

85 Toyota MR2 (Blu)

83 Mazda RX-7 Mariah Widebody

2016 Toyota Tacoma Quad Cab LB TRD OffRoad

2005 Toyota Sienna, work van

85 Toyota Tercel SR5 4wd (The General)

85 Toyota Tercel GTS 4wd (4AGE Swap)

85 Toyota MR2 (Blu)

83 Mazda RX-7 Mariah Widebody